We have established the GB / T19001 Quality Management System for all production plants and conducted product quality certification. Various production plants have enhanced homogenization and quality control on raw materials, fuel, semi-finished products and finished products. All indicators of our products’ quality are higher than the national standards. Our production plants and the provincial quality inspection institutions or institutions of higher levels conduct comparative tests on a monthly basis to verify and improve the detection level.

Quality Control Consultants Limited (“QCC”), which is a subsidiary of the Company, has grown from testing concrete and cement to testing of a multitude of items ranging from soils, tiles to metal since 1986.

Precautions on Delivery, Transportation, Storage and Use of Cement

1. During transportation and storage, the cement shall not be moistened and mixed with debris.

2. Bulk and bag cement should be stored separately according to different manufacturers, product types, strength levels and batches. They should not be mixed together. Cement inventory are managed according to the method of first in first out and last in last out.

3. If the cement has been stored for too long, re-sampling is required to make sure it fulfills the relevant standard before use. Due to the rainy season in the South, it is suggested to finish the products within 7 days.

4. According to the characteristics, design and construction requirements and site environment of different projects, appropriate types and strength level of cement should be chosen. For the same part of a construction project, cement from the same manufacturer, type and strength level should be used.

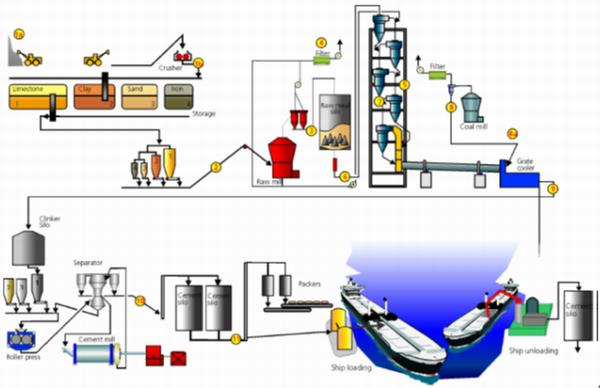

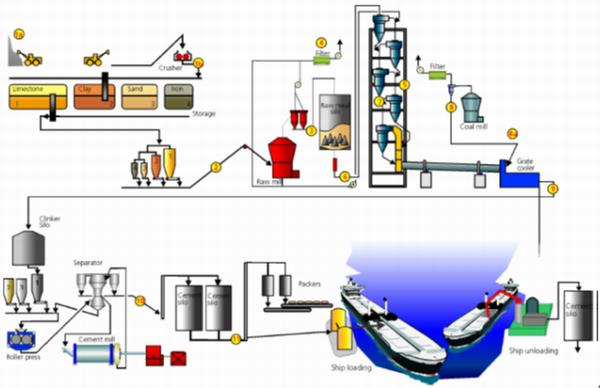

Manufacture Process